Certification

Lloyd’s Register "Digital Twin Ready"

HermAce is a tool capable of detecting, diagnosing, and predicting errors in the Furuno Equipment using Digital Twin technology. Its quality and reliability have been evaluated by the British Maritime Classification Society Lloyd's Register, and we have acquired the "Digital Twin READY" certification for a Digital Health Management (DHM) developer in the marine and offshore industry. For more information, click here.

ClassNK「Innovation Endorsement」

HermAce has acquired the "Innovation Endorsement for Products & Solutions" certification by Japan Maritime Classification Society ClassNK. This tool was evaluated for improving maintenance quality by collecting and visualizing data from Furuno equipment installed on ships and performing real-time monitoring. For more information, click here.

Features

Innovative Troubleshooting Solution

HermAce is a tool designed to allow constant monitoring of on-board equipment anywhere and anytime you need. Additionaly, it allowsenhanced monitoring by sending information to both the crew and the shore-based team for better decision making and quick actions.

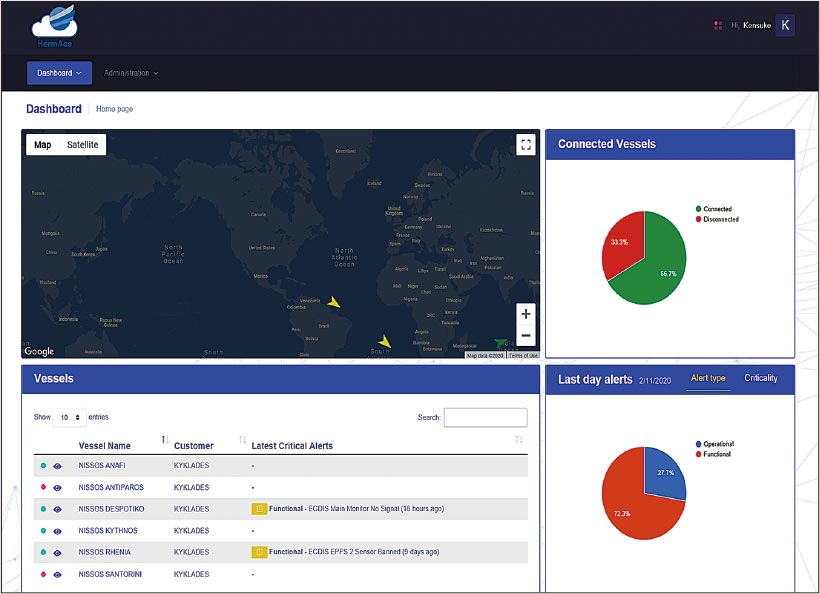

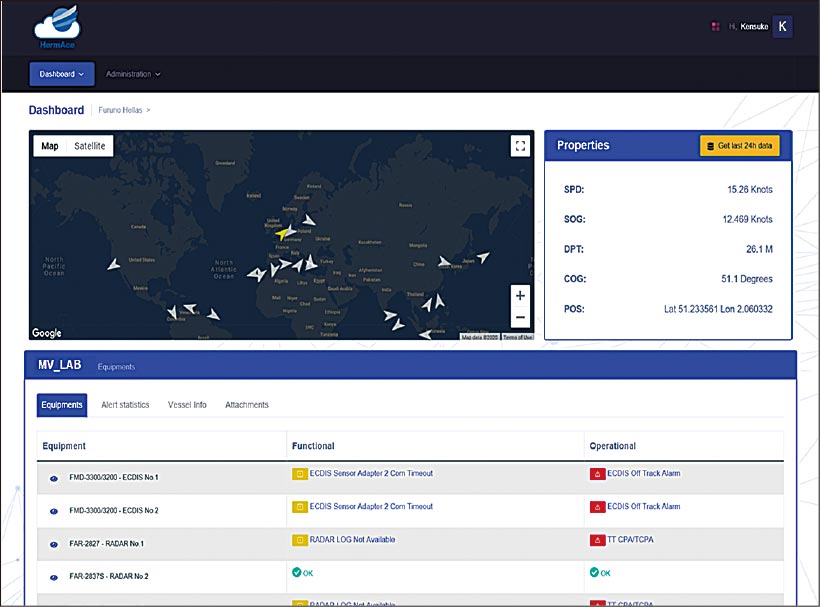

User Friendly Interface

HermAce's Web-portal's user-friendly interface allows for easy monitoring and smooth navigation thanks to the real-time update of reports and analytical data.

E-Mail Alert Notification

If an important alert is received, a notication will be immediately sent to the designated e-mails with troubleshooting instructions without having to wait for a crew member's report.

Real-time Remote Monitoring

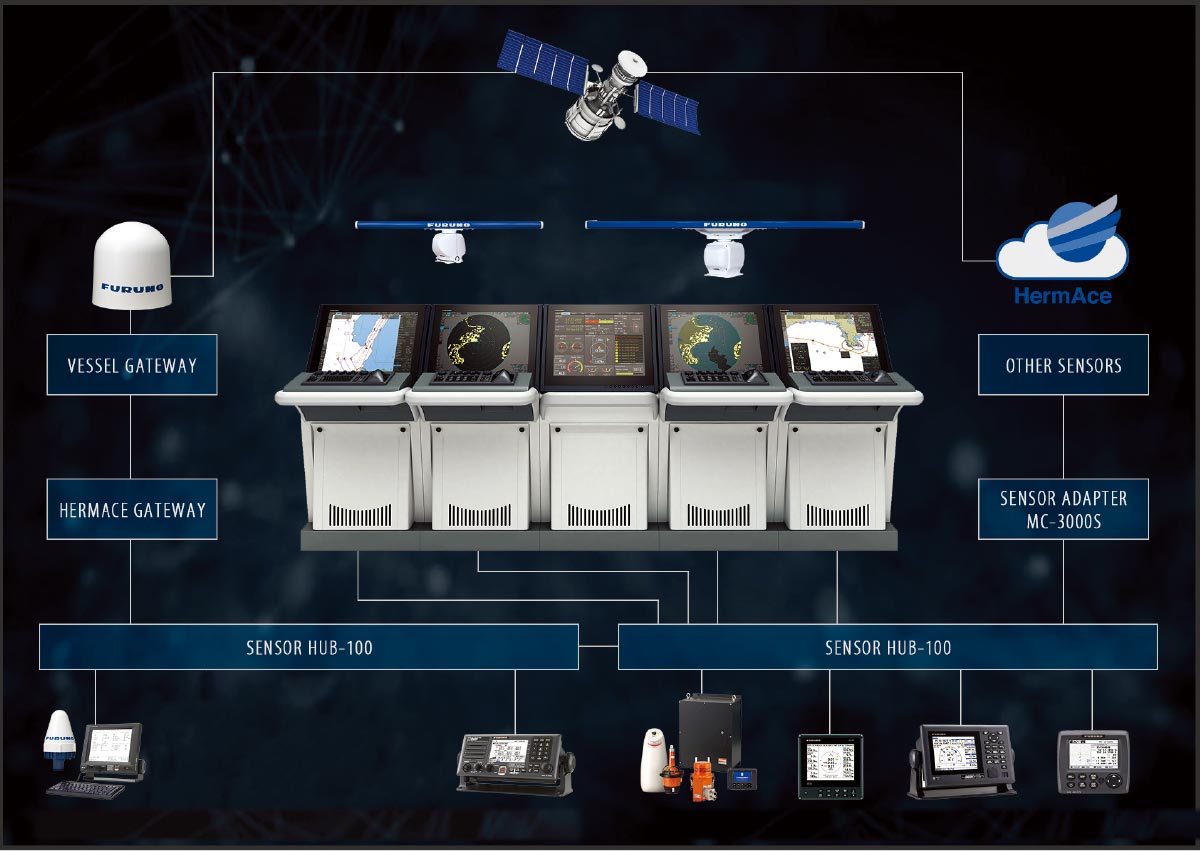

HermAce is a cloud system connected to Furuno's navigation and communication equipment on board. Critical data pertaining to the vessel’s equipment is collected through a smart device; then transmitted to and stored on cloud infrastructure, making it available to customers through a web-portal.

Reliable Connectivity

Thanks to an intelligent algorithm, extreme data compression makes it possible to considerably reduce the volume of information and to transmit this information to a remote server via a satellite communication system such as VSAT.

Easy Access Anywhere, Anytime

The portal can be accessed anywhere and anytime, provided that an internet connection is available, and it can be viewed on any computer or smartphone.

Menu

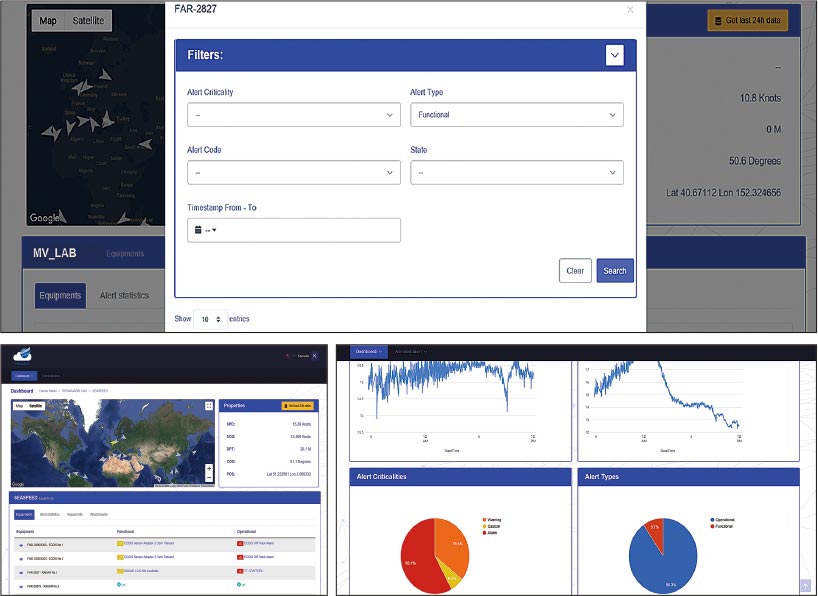

Vessel’s Top Menu

All network data can be viewed so that any problem can be quickly resolved.

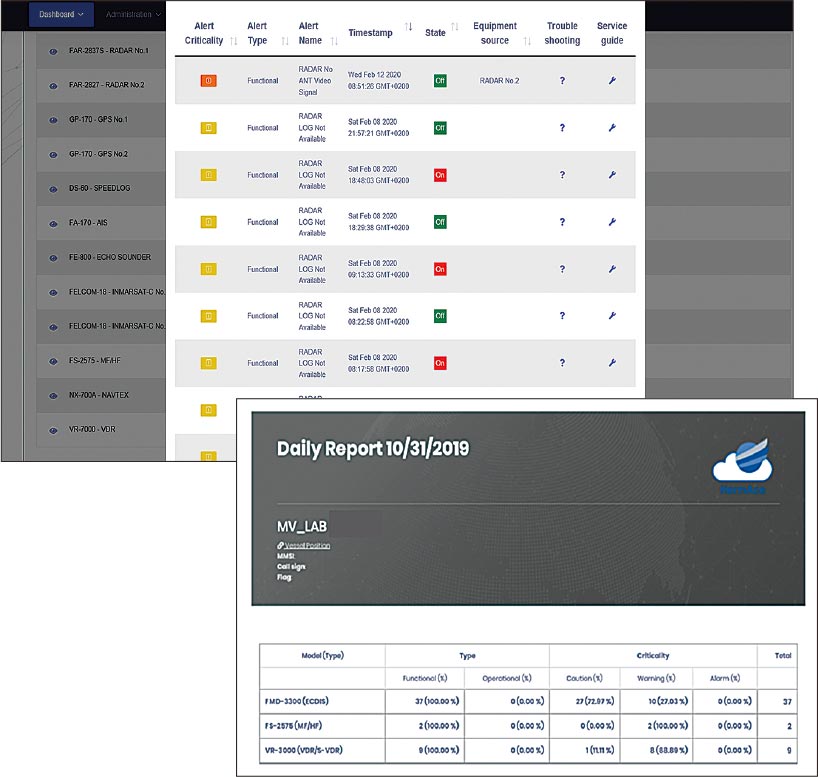

Alert History, Daily Report

On the portal, it is possible to display the history of alerts and to export a daily report of these events.

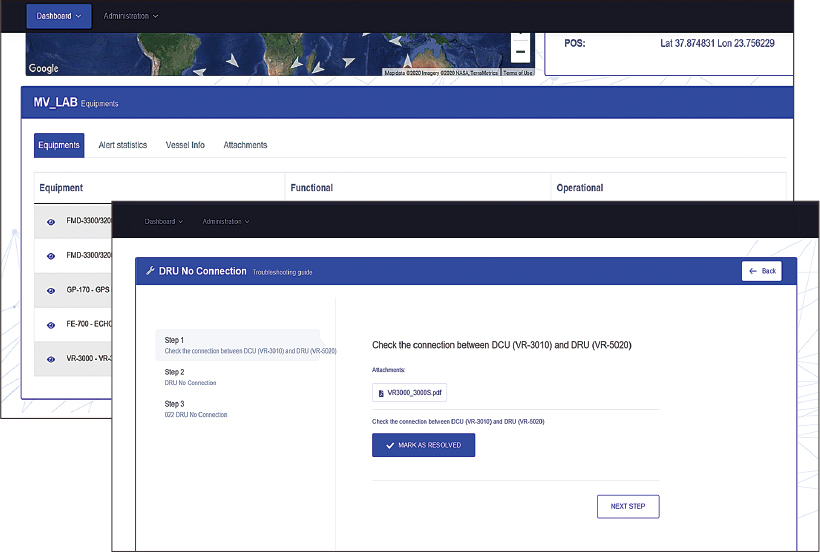

Troubleshooting

Achieve cost reduction and efciency gains, thanks to a powerful andcomprehensive troubleshooting solution.

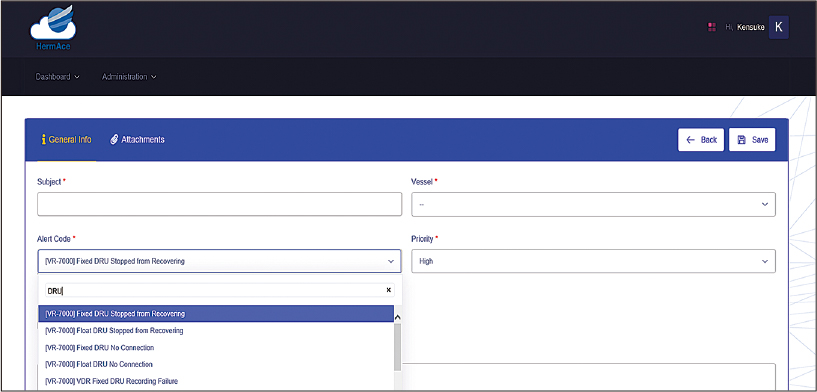

Ticketing

In case further support is needed, ticketing functionality is available through the HermAce portal, this function helps keep the record of events occuring inside the portal and strengthen the communication with Furuno's support team.

Interconnection Diagram